Cutting and Drying End Grain Cookies

In this article and video I show my process of cutting, stabilizing and drying end grain cookies using a large chainsaw mill, Pentacryl and air drying. I'm not sure who coined the term "Cookie" but you'll notice around the web they are refereed to as end grain slabs, end grain cookies, cookies and cross cut sections. This can make it somewhat tedious to locate information so hopefully this article will help answer questions and stop further research.

Cutting End Grain Slabs "Cookies"

There are a few different processes of cutting end grain slabs and each have their pros and cons. The methods that immediately come to mind use a regular bandsaw, bandsaw mill, chainsaw or a chainsaw with an attached mill guide like the one I have.

There are a few different processes of cutting end grain slabs and each have their pros and cons. The methods that immediately come to mind use a regular bandsaw, bandsaw mill, chainsaw or a chainsaw with an attached mill guide like the one I have.

Bandsaw & Bandsaw Mill

If you have a smaller log, a bandsaw might be perfectly acceptable but most will only handle a 6 - 12-inch diameter log. If you're lucky enough to have or know someone who has a bandsaw mill, you can step it up and do larger logs as long as you're not afraid of some tricky maneuvering. You won't be limited to a 6 - 12-inch diameter log but since these will be cut vertical you will be limited by the maximum height capacity of the mill and of course the maximum log width. If this is an option that will work for you, it will give the nicest end results as bandsaw mills generally provide a relatively smooth finish. (Relative to a chainsaw..)

Chainsaw & Chainsaw Mill

Some of the benefits from using a chainsaw are that nearly everybody has one and with the right bar you can surpass the capacity of even the largest and most expensive bandsaw mill. If you happen to have a large milling guide to go along with a big power house and a ridiculously long bar, then there aren't many trees that you can't get a beautiful end grain slab out of. Plus you'll be able to travel and mill on-site much faster and easier than even tow-able bandsaw mills. However, without a milling attachment like I demonstrated in the video, you will most likely end up with non-parallel cuts. If this is the case, a little time and a router sled will help achieve nice smooth parallel sides. You also won't get the best finish when using a chainsaw over a bandsaw mill as you are probably well aware that chainsaw's don't tend to leave the smoothest of finishes. Because of this, I plan on using a router sled even though my slabs should be parallel. I won't be removing a lot of material but I will hopefully be greatly reducing the amount of time I have to spend sanding and/or planing.

Some of the benefits from using a chainsaw are that nearly everybody has one and with the right bar you can surpass the capacity of even the largest and most expensive bandsaw mill. If you happen to have a large milling guide to go along with a big power house and a ridiculously long bar, then there aren't many trees that you can't get a beautiful end grain slab out of. Plus you'll be able to travel and mill on-site much faster and easier than even tow-able bandsaw mills. However, without a milling attachment like I demonstrated in the video, you will most likely end up with non-parallel cuts. If this is the case, a little time and a router sled will help achieve nice smooth parallel sides. You also won't get the best finish when using a chainsaw over a bandsaw mill as you are probably well aware that chainsaw's don't tend to leave the smoothest of finishes. Because of this, I plan on using a router sled even though my slabs should be parallel. I won't be removing a lot of material but I will hopefully be greatly reducing the amount of time I have to spend sanding and/or planing.

Stabilizing

Normal slabs can generally be dried with minimal cracking due to the majority of the moisture evaporating through the small section of end grain on either side of the slab. Since cookies are nearly all end grain, unless precautions are taken they dry out way too fast which almost always results in cracking. Depending on the species of wood, size of slab, humidity, wind, luck, etc... you might be able to get some cookies that don't crack without stabilizing first. If you don't want to take that chance then you'll need to get familiar with a product many people swear by. Pentacryl by Preservation Solutions is a green wood stabilizer that goes on clear, doesn't stain the wood and actually reduces dry time. Wait a minute.. isn't reducing dry time counterproductive you say? More on that later.

Normal slabs can generally be dried with minimal cracking due to the majority of the moisture evaporating through the small section of end grain on either side of the slab. Since cookies are nearly all end grain, unless precautions are taken they dry out way too fast which almost always results in cracking. Depending on the species of wood, size of slab, humidity, wind, luck, etc... you might be able to get some cookies that don't crack without stabilizing first. If you don't want to take that chance then you'll need to get familiar with a product many people swear by. Pentacryl by Preservation Solutions is a green wood stabilizer that goes on clear, doesn't stain the wood and actually reduces dry time. Wait a minute.. isn't reducing dry time counterproductive you say? More on that later.

Drying

Drying

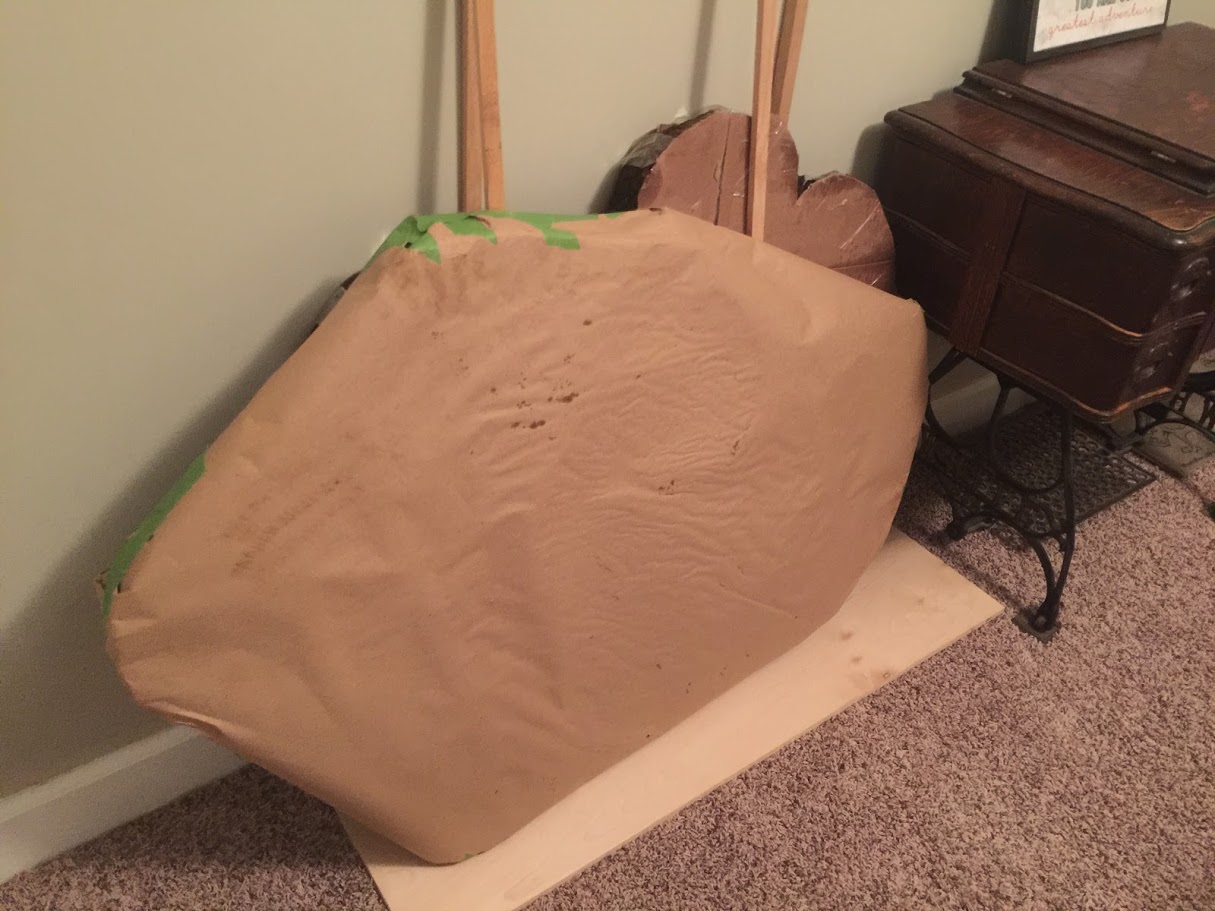

After the cookies have been saturated and stabilized, you'll want to allow them to drip dry and do the best you can to slow down the drying process. Depending on the size of your cross cut, you can do this by placing them in a cardboard box, taping cardboard over the end grain and/or painting the end grain with a sealer like AnchorSeal.  In my case, I taped cardboard over one and then wraped myself a nice present of the other using some thick brown paper. Then you'll want to store them separated by stickers in a vertical position somewhere out of direct sunlight and with minimal airflow. I put mine in our guest room even though my wife was sure they would smell up the whole house. (They didn't.) After that you'll just have to wait a few months or more depending on the thickness.

In my case, I taped cardboard over one and then wraped myself a nice present of the other using some thick brown paper. Then you'll want to store them separated by stickers in a vertical position somewhere out of direct sunlight and with minimal airflow. I put mine in our guest room even though my wife was sure they would smell up the whole house. (They didn't.) After that you'll just have to wait a few months or more depending on the thickness.

Waiting

I've seen claims that Pentacryl can reduce the dry time up to 90% but I plan on leaving my slabs alone for at least 3 to 6 months if not more. I've got a basic moisture meter but I don't want to risk ruining these things by getting in too much of a rush. This is probably the hardest part of the whole process just as it is with the rest of the wood I mill. At least it will give you plenty of time to figure out what kind of table legs to use.In roughly half a year I plan on turning these beautiful cross cut, end grain slab cookies into a hopefully gorgeous set of end tables. If you sign up for the newsletter, you will be one of the first to know when that happens.

I've seen claims that Pentacryl can reduce the dry time up to 90% but I plan on leaving my slabs alone for at least 3 to 6 months if not more. I've got a basic moisture meter but I don't want to risk ruining these things by getting in too much of a rush. This is probably the hardest part of the whole process just as it is with the rest of the wood I mill. At least it will give you plenty of time to figure out what kind of table legs to use.In roughly half a year I plan on turning these beautiful cross cut, end grain slab cookies into a hopefully gorgeous set of end tables. If you sign up for the newsletter, you will be one of the first to know when that happens.