Ultra Smooth Finishing Method

There are few things worse than finishing a project just to have it not appealing to the touch. Don't you hate it when you're finally getting around to dusting and your duster keeps getting caught on whatever you're dusting? NO MORE! I've had a lot of questions on how I get my finishes smooth to the touch so here's a quick video and detailed article on my process.

There are few things worse than finishing a project just to have it not appealing to the touch. Don't you hate it when you're finally getting around to dusting and your duster keeps getting caught on whatever you're dusting? NO MORE! I've had a lot of questions on how I get my finishes smooth to the touch so here's a quick video and detailed article on my process.

A little preface about this topic

You can really go down a rabbit hole when getting on the topic of finishing. There are thousands of techniques and many people are very opinionated. There are some hard and fast rules on what things should and can be mixed with others but there are also lots of fairly loose rules that are left open for interpretation. That being said, articles about finish can be somewhat controversial so if you have any comments, suggestions or other finishing techniques you would like to share, please don't hesitate to comment down below.

Where does and doesn't this finish Belong?

When thinking about applying a finish, I've never really considered this particular method for the inside of cabinets or pretty much any vertical surfaces. I generally only apply this much effort to a top surface such as a table, counter, fancy shelf or at least something that will have lots of hands on it such as a box.

The Surface for this Demonstration

The surface I am using in this demonstration is a large counter top made out of one of the softer hard woods. It is comprised of roughly 2x6-inch boards and had two sections that add up to about 14-feet in length. The clients wanted it rustic and used looking but very smooth so their duster wouldn't catch and splinters weren't to be found. I did my best utilizing random objects around my shop to scratch, dent, mar and gently damage in hopefully what ended up being no noticeable pattern. This of course left many deep scratches and some tear out which would be a bad recipe for splinters and general crappy finishes.

The surface I am using in this demonstration is a large counter top made out of one of the softer hard woods. It is comprised of roughly 2x6-inch boards and had two sections that add up to about 14-feet in length. The clients wanted it rustic and used looking but very smooth so their duster wouldn't catch and splinters weren't to be found. I did my best utilizing random objects around my shop to scratch, dent, mar and gently damage in hopefully what ended up being no noticeable pattern. This of course left many deep scratches and some tear out which would be a bad recipe for splinters and general crappy finishes. After "aging" this counter top, it got a thorough sanding with some 220-grit sandpaper and my random orbit sander. Not thoroughly enough of a sanding to remove all of the destruction that I so carefully applied though. A single coat of MINWAX 233 English Chestnut was applied to match it with some of the surroundings of its destination.

After "aging" this counter top, it got a thorough sanding with some 220-grit sandpaper and my random orbit sander. Not thoroughly enough of a sanding to remove all of the destruction that I so carefully applied though. A single coat of MINWAX 233 English Chestnut was applied to match it with some of the surroundings of its destination.

Getting Supplies

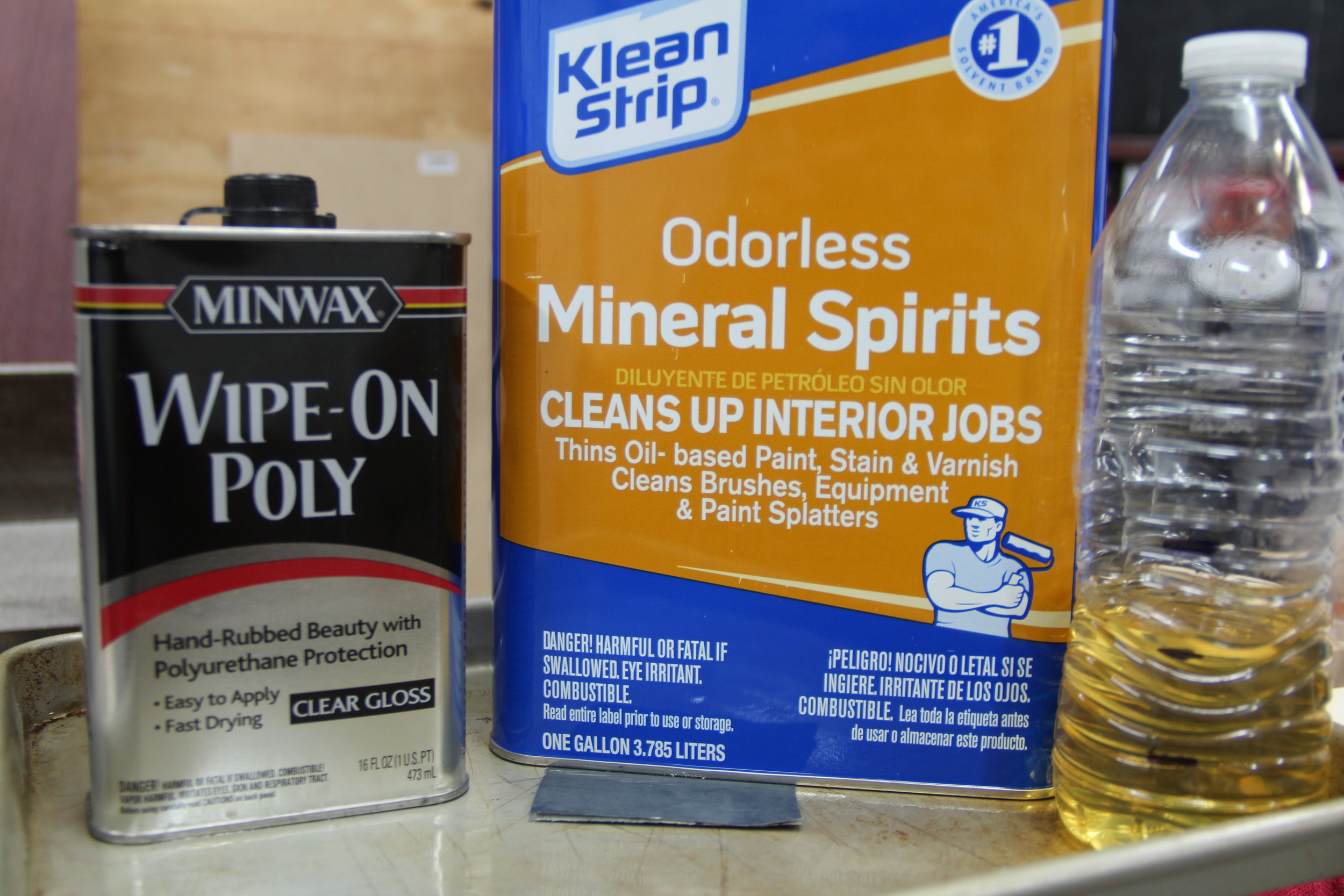

First things first, you'll need some supplies. I prefer to use MINWAX because it's easy to get and apply but if you have something else, substitutions are more than welcome.Here's what I generally use:

- MINWAX WIPE-ON POLY

- Odorless Mineral Spirits (Super cheap at big box stores.)

- Nitrile Gloves

- Wet/Dry Sandpaper (At least 400-600 grit)

- Assuming you already sanded up to 220 before finishing.

- Cut-up clean t-shirt

- Respirator

- Empty Container (I prefer a water bottle with a sports squeeze top.)

Mixing up a Batch

I like to thin my wipe-on poly quite a bit. The benefits of doing this is that it makes it easier to apply, self levels faster and much faster drying. It also helps provide additional lubricant for the wet sanding process. The biggest downside of thinning it out is.. well it's a thinner finish which means you will need to add a couple extra coats.Most of the time I stick with a 2 parts mineral spirits to 1 part poly blend. There are times when I'll go down to a 50/50 blend when I'm trying to build up one of the first layers faster but this means you'll have longer dry times and that particular coats finish won't be quite as smooth. I like to measure out my container into thirds so I can get a repeatable mixture. You might want to play with this blend over time to find out what works best for you.

I like to thin my wipe-on poly quite a bit. The benefits of doing this is that it makes it easier to apply, self levels faster and much faster drying. It also helps provide additional lubricant for the wet sanding process. The biggest downside of thinning it out is.. well it's a thinner finish which means you will need to add a couple extra coats.Most of the time I stick with a 2 parts mineral spirits to 1 part poly blend. There are times when I'll go down to a 50/50 blend when I'm trying to build up one of the first layers faster but this means you'll have longer dry times and that particular coats finish won't be quite as smooth. I like to measure out my container into thirds so I can get a repeatable mixture. You might want to play with this blend over time to find out what works best for you.

Finally... Applying the Finish

This is going to be a multi part process where you will rinse and repeat with some minor changes. Luckily, the mineral spirits will evaporate pretty fast which will potentially allow you to re-apply an additional coat in as little as an hour or less. This of course depends on your blend ratio and how much you doused onto your surface in the first step.

Step 1: Wiping it on

This is the easiest step but you will want to make sure you show a little restraint. Instead of pouring TONS on here and flooding the entire surface, you'll want to just make sure all of it gets  sufficiently wet. I generally wet my rag with the finish and wipe it around. The first and second coats will require more finish to keep it wet but the goal here is to apply just enough finish that the entire surface is wet for the entire process but not so wet that you are splashing around when sanding.If you accidentally or even intentionally added a TON, you'll just have a bigger mess and more work ahead of you to rub it down. That being said, I'm going to contradict myself and say that on the beginning coats, it might be beneficial to add a little extra and leave it wet in the 3rd step to help build up a thicker coat.

sufficiently wet. I generally wet my rag with the finish and wipe it around. The first and second coats will require more finish to keep it wet but the goal here is to apply just enough finish that the entire surface is wet for the entire process but not so wet that you are splashing around when sanding.If you accidentally or even intentionally added a TON, you'll just have a bigger mess and more work ahead of you to rub it down. That being said, I'm going to contradict myself and say that on the beginning coats, it might be beneficial to add a little extra and leave it wet in the 3rd step to help build up a thicker coat.

Step 2: Wet Sanding

If you have applied stain to your surface, you might want to skip this step for the first and possibly second coat to allow a thicker finish to build up before wet sanding. If you do want to sand during the first and second coats, you will want to take it easy.Now that the surface is thoroughly soaked with finish, you'll want to get out your wet/dry sandpaper and lightly sand the entire surface area. If you already sanded everything to 220-grit then you might start with 320-grit or higher. My surface was sanded to 220-grit before getting stained so I decided to start with 400-grit and move to 600-grit after my 3rd coat to get the super soft and smooth finish I was looking for.When wet sanding my surfaces, I'll generally do three passes with each coat. I'll go down and back the full length of the surface while sanding in little circles and then end it by going with the grain. During this process you'll want to listen and feel how it's going. You'll be able to tell what parts might need a little more sanding. If have a stain on, you'll want to be careful not to sand too much or you might sand right through the stain. If any parts get too dry during the sanding process, just apply a little more finish. Hopefully what's left in your damp rag is enough.

Step 3: Buff it Out

Using your still damp rag, you'll pretty much want to follow the same steps you did for the wet sanding. Rub the entire surface down in little circles and big circles until the entire things has been buffed pretty much dry. You'll want to end it off with wiping it down with the grain in long gentle passes. If this is one of the first couple coats, you might have put on a little more finish and will have to leave it wet. Just be careful with the last pass to make sure it's gentle and with the grain.With the last coat or two, you'll want to buff it until it's completely dry. It might sound awful but at this point it will already be so smooth that it won't take much finish to wet it all down in the first step which will make it dry extra fast.

Step....: Rinse and Repeat

How many times do you rinse and repeat? Well, that depends on a few variables such as: How durable does it need to be, how hard is the wood, how patient are you? I would recommend 5 coats but you might want to do 3 and I might want to do 7. It really depends on how thick of a finish you want but you will almost always want a minimum of three since you won't start getting to the ultra smooth level until that point.As mentioned before, you might skip step 2 for the first coat or two since at that point you are really just trying to build up a finish. You'll also want to progress up in your sandpaper levels and end with at least 400-grit but I would prefer 600-grit or higher. I probably shouldn't say you can re-coat faster than recommended by the manufacture (MINWAX - 3 Hours) but when thinning it out this fast, I've re-coated in less than a half hour. I should mention that my shop was also nearing 100° at the time which I'm sure didn't slow down the evaporation of the mineral spirits.

ENJOY!

With this finishing method, most of the character from the "rusticizing" should be retained while hopefully removing any open splinters that might cause issues down the road. When people come into my house, they are amazed at how smooth the top on my old workbench turned sofa table is. I think that you, your guests or clients will get a lot of enjoyment out of how smooth their surfaces will be.

Don't Forget

I don't think I'll be ending this one with a "Lessons Learned" like I do with most project articles so instead I'm going to just summarize everything so you don't forget.The finish I use is composed of 2 parts mineral spirits to 1 part wipe on polyurethane. After starting with a smooth surface sanded to at least 220-grit, I like to build up a layer or two of my clear coat and then start wet sanding it with 400 and then 600 grit sandpaper during the finishing process. Next, I buff the poly until nearly or completely dry making sure to end the sanding and buffing process in the direction of the grain. Keep adding coats until your surface is satisfyingly smooth and then add a few more.If you have suggestions or additional methods of achieving a ridiculously smooth and durable finish let me know in the comments! As I mentioned in the beginning of this article, there are more ways to apply wood finish than there are to skin a cat so I'm sure plenty of people will have their opinions. If you are one of those people, lets everybody know what you do in the comments below.